Dilution & Blending

Caustic Dilution, Buffer Dilution, and Buffer Formulation

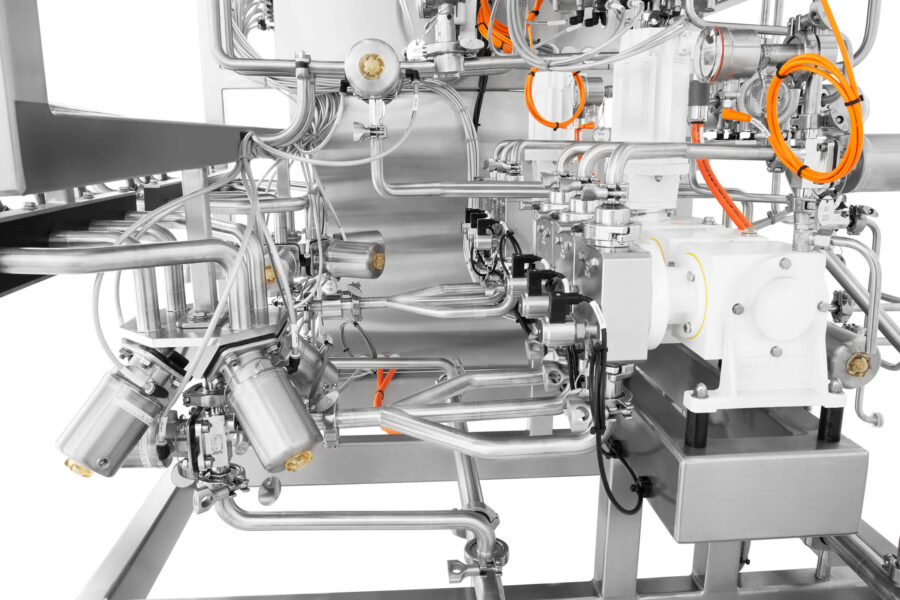

YMC manufactures a variety of dilution and blending systems – including standard and custom systems – for direct dilution of premixed buffer concentrates, custom single-step and multi-step caustic dilution systems, and custom buffer formulation systems.

Our Buffer In-line Dilution (BID) systems with digitally controlled diaphragm metering pumps and optimized fluidic design deliver a precise and accurate flow of both buffer concentrate and diluent used in downstream processing. This ensures better control of final buffer composition and minimizes the variation of critical quality attributes such as ionic strength, concentration, pH, and conductivity.

Offering both standard platforms and customized solutions, YMC can:

- Automate complex dilution processes

- Design for aqueous or solvent-based feedstocks

- Minimize operator exposure to potential chemical hazards

- Reduce labor costs associated with buffer preparation

- Reduce the footprint of your tank farm by allowing the use of concentrates

- Provide systems in special alloys for aggressive solutions

- Increase scheduling flexibility by enabling the use of buffer concentrates in durable totes or single-use bags

- Provide systems which are ATEX or Class I Div II rated.

- Provide a centralized caustic dilution system (with optional temperature control) to provide the variety of concentrations used throughout the facility from concentrate (up to 50%).

What Sets Us Apart?

YMC has the process expertise to offer guidance to our customers and design custom dilution and blending equipment that fits their needs.

Below are some options that we offer for our custom systems.

If you have a different need or unique situation, let us help you create the solution.

Caustic dilution

- Heat exchangers (temperature control)

- Storage tanks, upstream and/or downstream

- Distribution systems (pumps and valves)

Buffer formulation (aqueous and solvent)

- Heat exchangers (temperature control)

- Storage tanks, upstream and downstream

- Distribution systems (pumps and valves)

- Hazardous location ratings (Cl.1, Div.1, Div.2; ATEX Zone 0, 1, 2)

Direct dilution systems (aqueous and solvent)

- Modified/extended dilution ranges

- Heat exchangers (temperature control)

- Storage tanks, downstream

- Hazardous location ratings (Cl.1, Div.1, Div.2; ATEX Zone 0, 1, 2)