Custom Process Systems

Our Production With Your Design

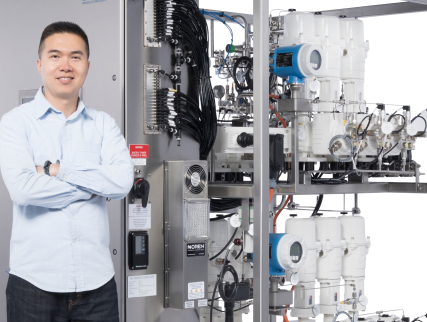

Designed to each user’s specification, custom skids reflect the unique insights of the user and YMC engineers.

We develop and supply OEM and custom systems for biotechnology and pharmaceutical customers who seek to take advantage of the benefits offered by our highly skilled workforce and procedure-driven fabrication techniques.

YMC Process Equipment

Our design engineers have years of experience with a wide variety of process systems. We are vertically integrated with design, automation, fabrication, and installation all under one roof. We supply systems used in GMP environments, so we are able provide the necessary documentation and testing required to facilitate your validation efforts.

State-of-the-Industry Materials and Shop

To ensure you receive the most robust and easy-to-maintain equipment, we work with state-of-the-industry components which are well known and supported. We are trained to handle specialty materials such as AL-6XN and Hastelloy. Our welding, fabrication, polishing, inspection, and testing standards consistently meet the highest global standards, thanks to the rigorous Standard Operating Procedures and Quality Plans built into everything we do.

Our 21,000 s.f. (2000 m2) facility has produced equipment used all over the world. We’ve shipped multiple systems to Europe and Asia in addition to the many we have delivered within the United States.

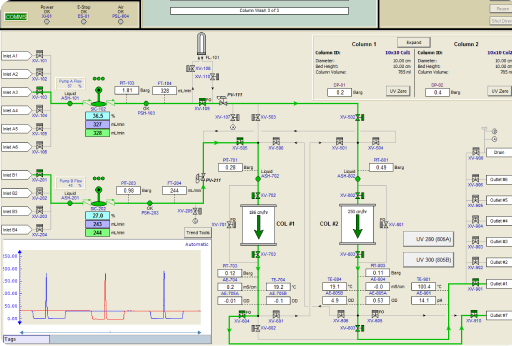

Your Software, Our Software, No Software

Our expertise in PLC-based (Rockwell/Allen Bradley) equipment can be applied to your OEM or custom system for a turnkey project, or you can bring your team’s software to our hardware.

Alternatively, we can build a “naked” skid, which you can integrate into your site using a third-party automation partner.

To see how you can benefit from a higher standard of equipment—or to get answers to specific capabilities questions—please contact us and let us know how we can help.